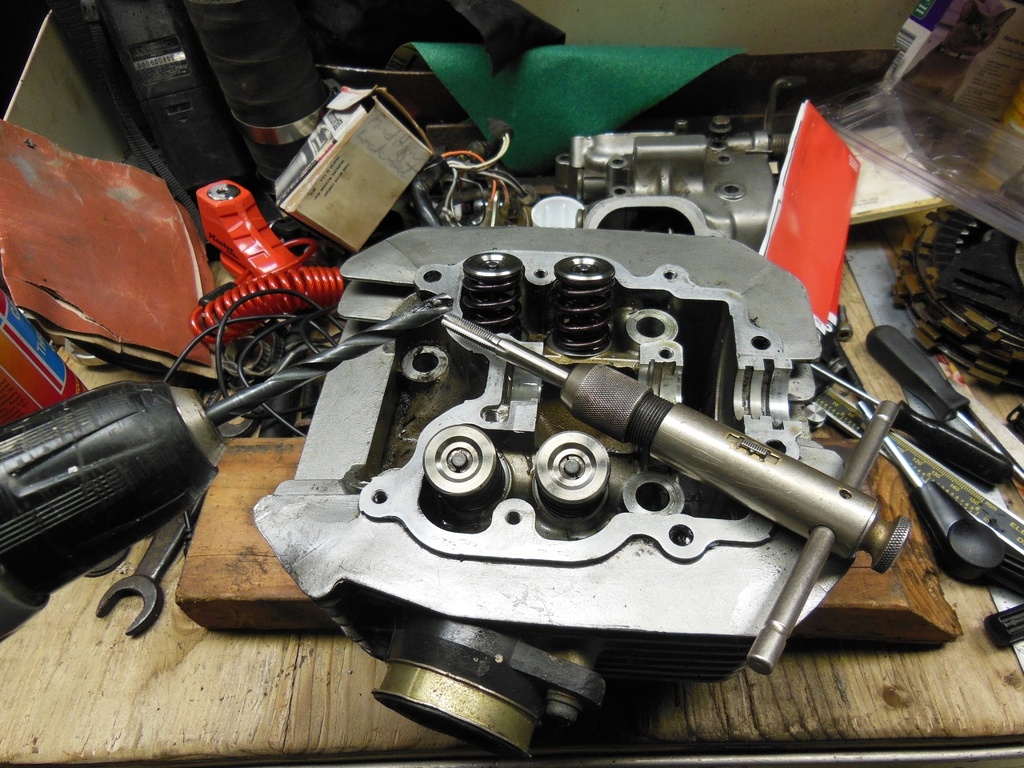

So as you may recall I just bought my DR350S only to immediately tear it down. A previous owner stripped one of the four bolts on the cylinder head cover over the camshaft. These bores are under positive oil pressure so it will produce a sizable oil leak.

After removing the cylinder head last week this evening I found my M6x1 Heli Coil set and repaired the damaged threads.

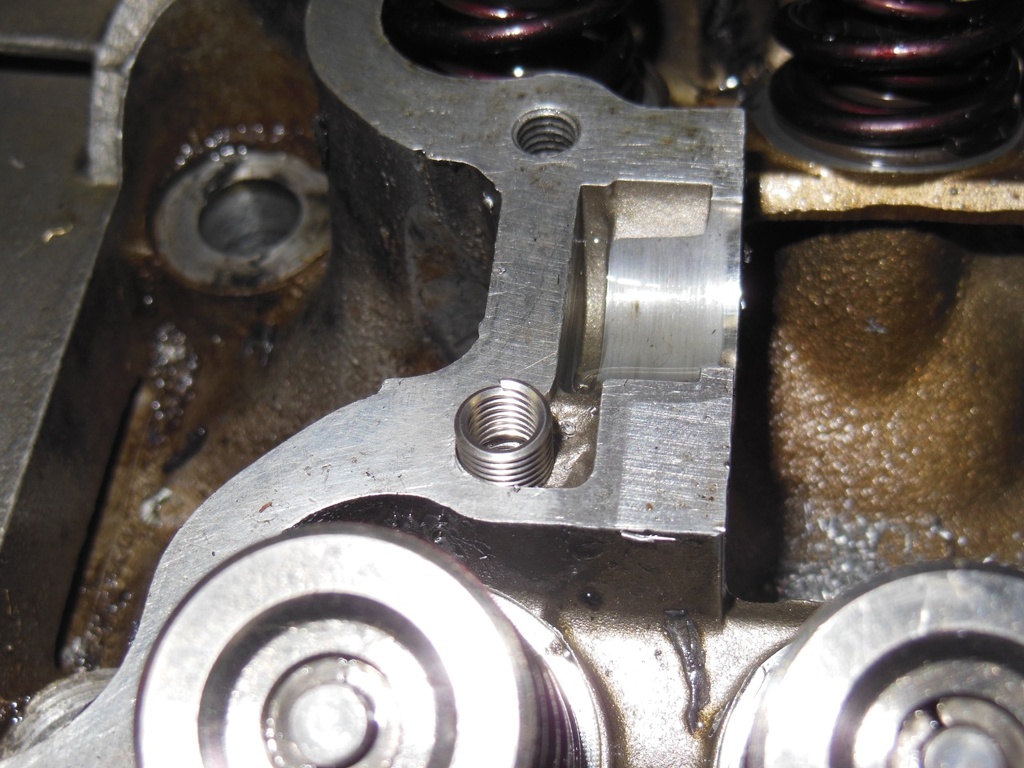

Heli Coils are a good way to repair threads. You drill the bore out to a larger size (in this case 1/4″), tap the hole, then thread the insert into place.

Heli Coils aren’t very good for through holes, they have a tendency to get hung up on the bolt and be pushed out. Because of this when I drilled the hole I stopped short of going all the way through. I sized the proper distance by putting the cylinder head cover back on, removing the washer, and dropping a bolt in place. I stopped when the bolt was flush on the cover. That will give me a small bit of extra room on the final product because of the sealant and bolt gasket/washer.

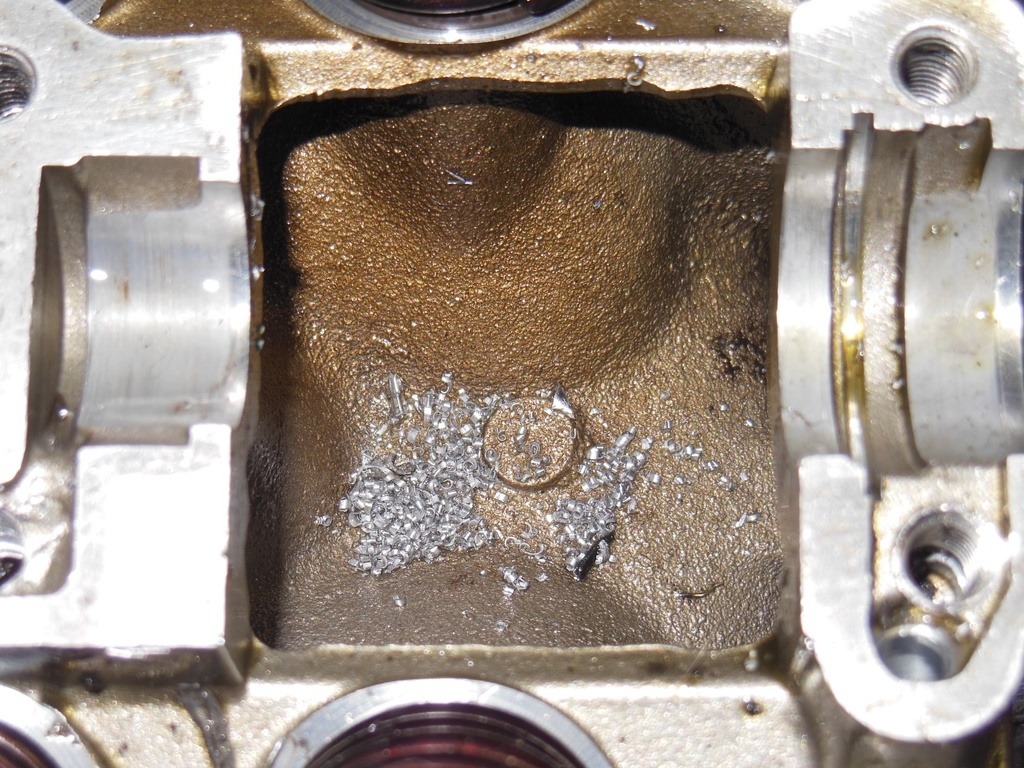

If you’re not familiar with threading bores you don’t just run the tap in the hole in one shot. You move it in small increments, with steel I typically go a quarter turn then back off, run it back to where I was cutting and go an additional quarter turn before backing off again. This cleans the metal shavings out from the cutting heads on the tap and deposits them into the flutes. With aluminum I’m a bit more careful and only go about 1/8 of a turn before backing off.

This is why I removed the cylinder head before doing this job. I was not confident I could control all the shavings if I didn’t remove the head. Plus, as an unknown motorcycle this gave me a good chance to look at the engine in detail.

The tang engages in the driver tool. There are a few different brands that have different types of tools.

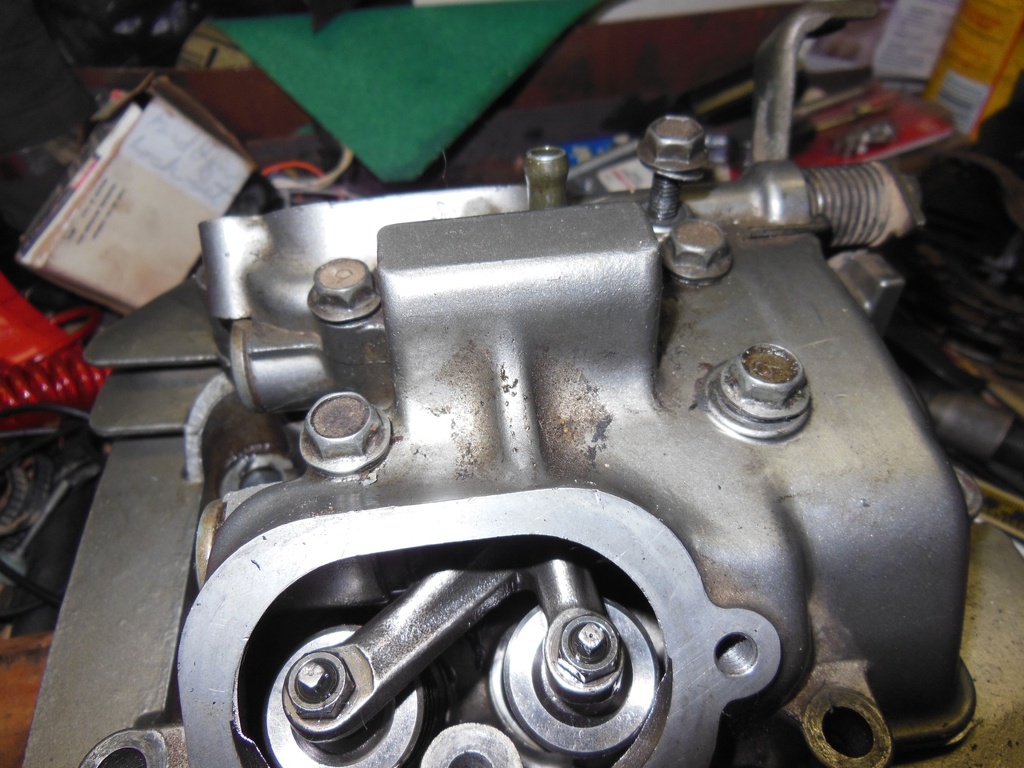

On point to remember. After you have the coil completely seated in the bore take a small punch and punch the tang out. Be careful to keep track of this piece as it is hardened steel and could cause serious havoc inside.